Solutions for the automotive industry

TRIOPTICS brings the complex driver assistance systems of the automotive industry onto the road.

We support manufacturers and suppliers in their task of ensuring the quality, longevity and sustainability of their systems. Our system solutions for active alignment and assembly enable the mass production of camera modules with appropriate testing technology. Get to know some of our innovations, which are extremely important for autonomous vehicles. Make the change.

Active alignment & testing of ADAS cameras

Even with a perfect lens system, the image quality of a complete camera deteriorates if the lens is poorly aligned with the sensor. This effect is amplified with the increasing performance of ADAS camera modules and the higher resolution of sensors. For this reason, the high-precision active alignment of optics and sensor is necessary in the production of camera modules. With our ProCam® technology, the sensor is aligned with the camera optics in up to six degrees of freedom with sub-micron/sub-arcmin resolution. The components are focused, centered, tilt adjusted and rotated in one single alignment step.

Optical alignment of Automotive lighting

Automotive lighting is a rapidly growing area of the automotive industry. Advances in digital headlights are an important milestone, offering tangible benefits in terms of visibility, safety and driving comfort. Intelligent headlights project safety-related information and symbols onto the road. This projection is made possible by intelligent and high-resolution light. In this way, lighting can guide, warn, and assist, making it an important lever for increasing road safety in particular. The necessary projection units with high-resolution LED pixel or micromirror matrix require precise optical alignment of the components. This is where our expertise and many years of experience in the alignment of optoelectronic systems come into play.

Alignment & testing of LiDAR systems

There is one thing that Flash-LiDAR, solid-state LiDAR or mechanical LiDAR scanning systems certainly have in common:The interaction of the optics and sensor chip of the emitter and receiver unit of the LiDAR sensor must be absolutely precise and perfectly aligned.

If the components are not precisely positioned, objects and distances cannot be reliably detected. In the worst case, this could compromise the safety of autonomous vehicles. Accordingly, perfect performance must be ensured from the first sample to the series product. We are happy to support you in choosing the right production method and manufacture the important first LiDAR prototypes together with you.

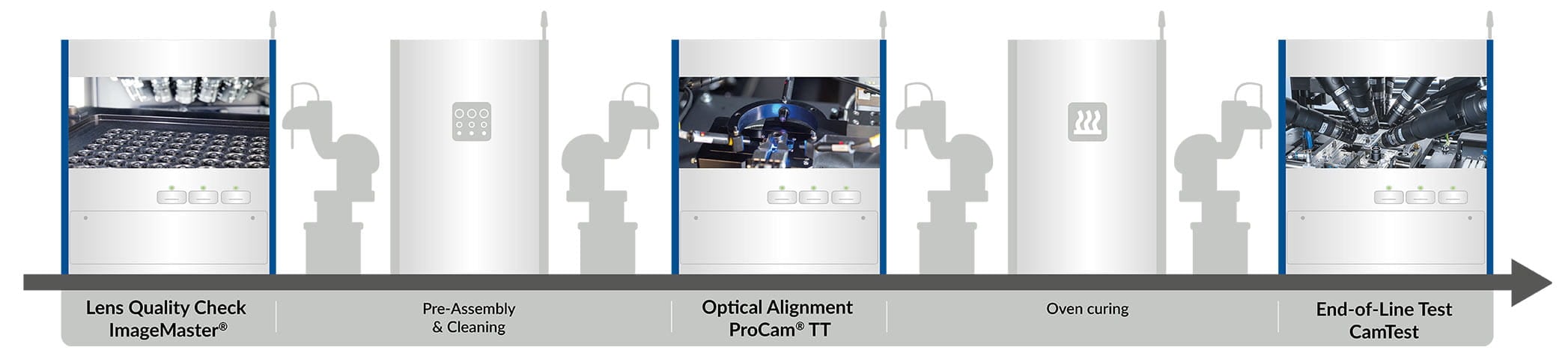

Active alignment & assembly of ADAS cameras

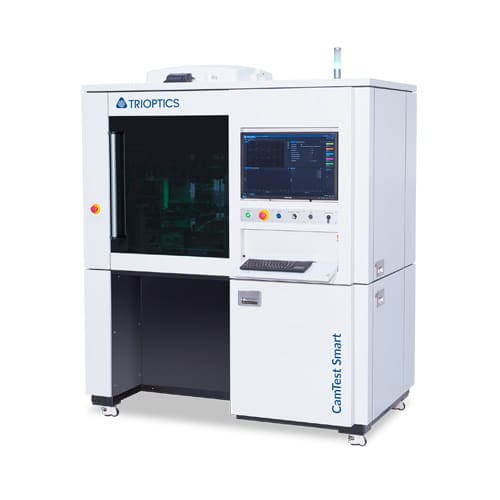

Advanced Driver Assistance System (ADAS) technologies for vehicles require highly reliable image processing systems and optical sensors to ensure safe and trouble-free operation on the road. Lives depend on it. These requirements are met by TRIOPTICS optical measurement and manufacturing systems. We integrate these high-precision metrology modules into mass production and provide solutions for the lens quality check, active alignment and end-of-line test for fully automated camera production lines.