OptiSpheric®

The standard for comprehensive testing of optomechanical parameters of lenses

OptiSpheric® is the industry standard for non-contact inspection of basic axial optical and mechanical parameters and is used worldwide to fully measure and qualify single lenses – as well as intraocular lenses – and optical systems. The world’s largest laboratories and major optics manufacturers rely on TRIOPTICS optical inspection systems.

They use the OptiSpheric® for reliable and reproducible axial measurement of effective focal length, back focal length, flange focal length, radius of curvature and modulation transfer function (MTF). Different product variants are available that are optimized for different applications and simplify the measuring process: manual or automated processes in different measuring ranges, the combination with OptiCentric®, measurement at further wavelengths and in-air and in-situ measurement for intraocular lenses. The easy-to-use software allows accurate measurement of the test samples at any time.

Reliable & traceable

User-friendly & fast

Efficient

Products

OptiSpheric® AF

The standard for testing lenses

The automated OptiSpheric® AF enables fast and reliable test results in automated test sequences.

- High precision autofocus

- Measurement of back focal length (BFL) as well as flange focal length (FFL) and curvature radius from ±5 mm up to ±490 mm

More information

The OptiSpheric® AF is available in four versions. These differ in their measuring ranges:

- OptiSpheric® AF 500:

- Focal lengths from -450 mm to +500 mm.

- Cut-off width, contact dimensions and radius of curvature from ±5 mm to ±490 mm

- OptiSpheric® AF 1000

- Focal lengths up to ±1000 mm.

- Focal length, contact dimensions and radius of curvature from ±5 mm up to ±490 mm.

- OptiSpheric® AF 1500

- Focal lengths up to ±1500 mm.

- Focal length, contact dimensions and radius of curvature from ±5 mm to ±790 mm

- OptiSpheric® AF 2000

- Focal lengths up to ±1500 mm.

- Focal length, contact dimensions and radius of curvature from ±5 mm up to ±990 mm.

OptiSpheric® IOL R&D

Comprehensive testing of IOLs in R&D

The OptiSpheric® IOL R&D allows the testing of intraocular lenses in research and development.

- Quick testing of single lenses in just 12 seconds

- ISO-compliant measurement of hydrophobic and hydrophilic lenses in air or in a heatable in situ eye model according to ISO 11979

- Power measurement with an accuracy of 0.3 % for all types of intraocular lenses

More information

The products of the OptiSpheric® IOL series represent the industry standard for intraocular lens inspection. Customers rely on the high-precision measurements in research and development as well as in production. The transparent measuring process allows the effortless determination of important parameters such as:

- Power (sphere, cylinder und addition)

- Effective focal length (EFL)

- Modulationtransferfunction (MTF and 2D-MTF)

- Pointspreadfunction (PSF and LSF)

- Orientation of the cylinder axis, orthogonality of the optical axis and deviation of the markers from the optical axis

- Radius of curvature (in air)

- Back focal length (BFL, in air)

- MTF focus scan („Through Focus Scan“)

- Energy distribution (MTF area)

- Streh ratio

- Visual inspection

The measuring systems are universally applicable for all types of intraocular lenses (monofocal, spherically aberrated lenses (EDOF), multifocal, trifocal, toric and aspherical IOLs (each diffractive, refractive or sector lens)) and allow the traceability of the measurement results to international, independent testing institutes such as NPL and NIST.

OptiSpheric® IOL PRO 2

Fully automated IOL measurement

OptiSpheric® IOL PRO 2 enables the inspection of intraocular lenses in production.

- High throughput with up to 100 lenses per tray

- ISO-compliant measurement of hydrophobic and hydrophilic lenses in air or in a heatable in situ eye model according to ISO 11979

- Power measurement with an accuracy of 0.3 % for all types of intraocular lenses

More information

The products of the OptiSpheric® IOL series represent the industry standard for intraocular lens inspection. Customers rely on the high-precision measurements in research and development as well as in production. The transparent measuring process allows the effortless determination of important parameters such as:

- Power (sphere, cylinder und addition)

- Effective focal length (EFL)

- Modulationtransferfunction (MTF and 2D-MTF)

- Pointspreadfunction (PSF and LSF)

- Orientation of the cylinder axis, orthogonality of the optical axis and deviation of the markers from the optical axis

- Radius of curvature (in air)

- Back focal length (BFL, in air)

- MTF focus scan („Through Focus Scan“)

- Energy distribution (MTF area)

- Streh ratio

- Visual inspection

The measuring systems are universally applicable for all types of intraocular lenses (monofocal, spherically aberrated lenses (EDOF), multifocal, trifocal, toric and aspherical IOLs (each diffractive, refractive or sector lens)) and allow the traceability of the measurement results to international, independent testing institutes such as NPL and NIST.

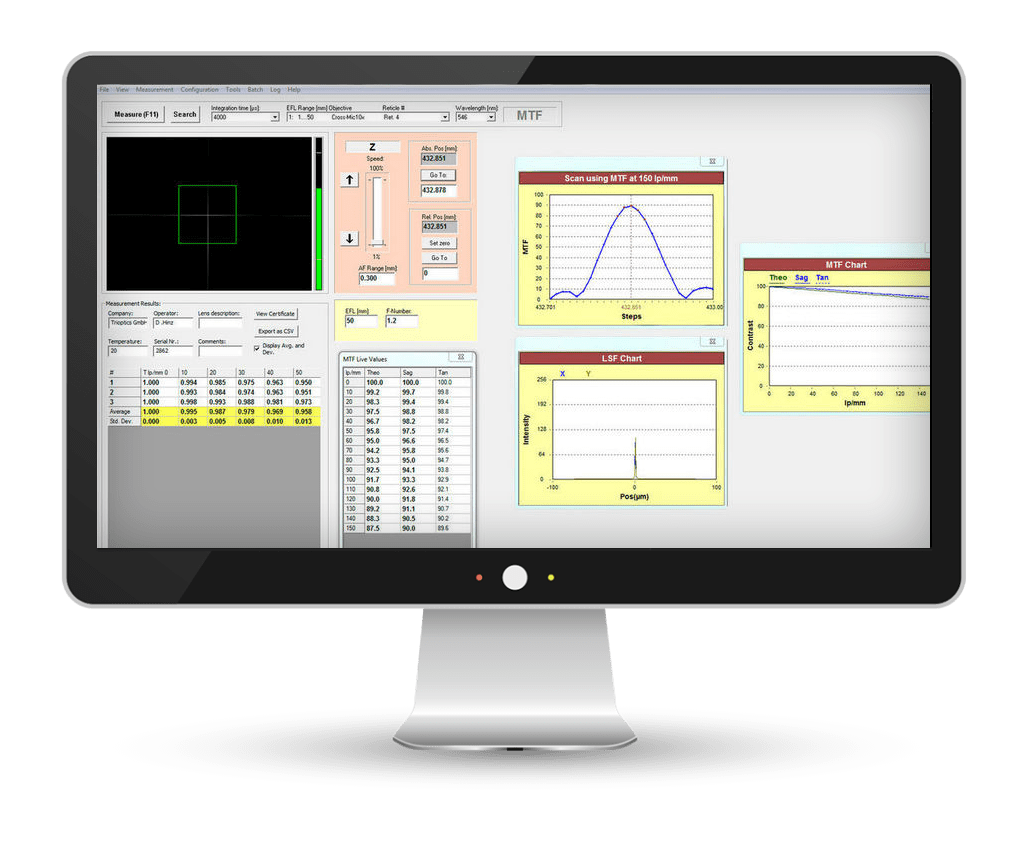

Software

OptiSpheric® Software

Simple and intuitive operation

The proven OptiSpheric® software meets the requirements of optical manufacturing in terms of simple and intuitive operation. It fulfills the highest demands for measurement speed and precision while providing consistent, reliable measurement results. The standard measuring sequences are supplemented by the possibility of configuring individual measuring sequences.

The software is convincing in many respects:

- Comprehensive, reliable functionalities that can be used both in production and in research and development

- Optimization of the test sequence through customer-specific programming of measurement and analysis sequences using script tooling – ideal for R&D laboratories

Fast working thanks to optional automated positioning of the appropriate reticle for the current application

Usage for IOL measurement

The software has been specially adapted for use in the field of IOL measurements.

Here it offers:

- Simple operation through predefined measurement processes for various IOL types

- Easy system setup with just a few clicks to start the fully automated alignment and measurement of batches with up to 100 IOLs

- Flexible, modular menu navigation that can be set up for different users (R&D, production, administrator)

More information

- Easy-to-understand measurement results with graphics displays and depiction of the camera image in real time

- Software-based correction of the refractive power in the event of temperature differences, defocusing and/or spherical correction

- Efficient data input and output by means of database communication and optional link to barcode reader

- Different modes permit, for instance, the preparation of individual measurement scripts

Upgrades

Lens holders

- Self-centering holders for lenses with an outer diameter from 3 mm to 35 mm with X-Y shifting device

- Self-centering holder for lenses with an outer diameter from 5 mm to 75 mm with X-Y sliding device

Measuring range and referencing

- Further optical attachments for the extension of the measuring ranges

- The OptiSpheric® is also available as a module for the OptiCentric®.

- Reference lenses

Illumination

- Additional light source for simplified BFL, FFL and curvature radius measurement

- Filter for measurement at further wavelengths

SortStation IOL for simple, fast and safe execution of all work steps upstream and downstream of the measurement:

- Loading of the trays:

The ideal positioning of the lenses is easily visible thanks to optimum illumination. - Sorting of the lenses after the measurement:

The test results are automatically transferred to the display and made visible directly at the location of the samples. The fulfilment of the pass/fail criterion is displayed in a green/red color scheme and the reliable assignment of each lens is made possible.

WorkStation IOL

The Workstation IOL is a complete workplace in which the Sortstation IOL is integrated. With its storage space for unused trays and other accessories, the Workstation IOL keeps everything in order. Drawer inserts support safe and organized storage. With the corresponding holder, the in-situ trays can be easily and safely set up for drying.

Customized lens holder

Others:

- Heating for model eye

- Corneas of various designs, e.g. with spherical aberration

- High-performance LED (light source)

- Customized lens holder for tray

- Filters for measurements at various wavelengths and photopic lighting

- High-resolution camera

OptiSpheric® Product request

Are you interested in a product and would like to receive a quote?

Whether you need advice or already have specific requirements, we will be happy to help you!

Use our contact form and get quick feedback from our experts.Our Newsletter – Your advantage in knowledge

Be one of the first to experience our product novelties and innovative application possibilities.