ProCam®

Active alignment, assembly and testing of camera modules and LiDAR systems

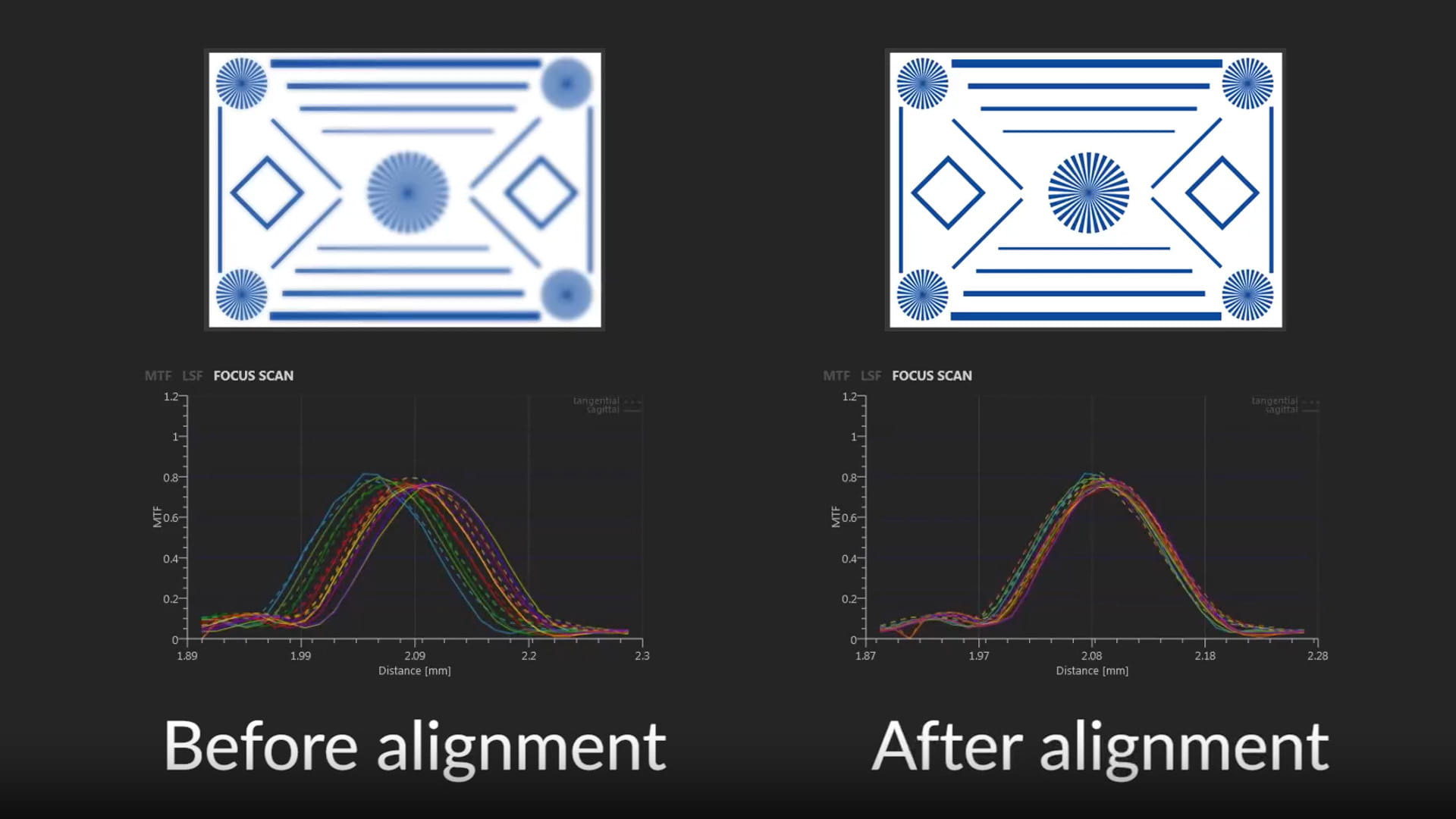

With the measurement and production equipment of the ProCam® series, we offer the latest solutions for the challenge of active alignment and series production of high-precision optical sensor systems. Active Alignment technology has a key function in optimizing the image quality of camera modules and LiDAR components. By providing optimal image quality across the entire field of view, active alignment is an established and efficient manufacturing process to produce high-end camera applications and LiDAR systems.

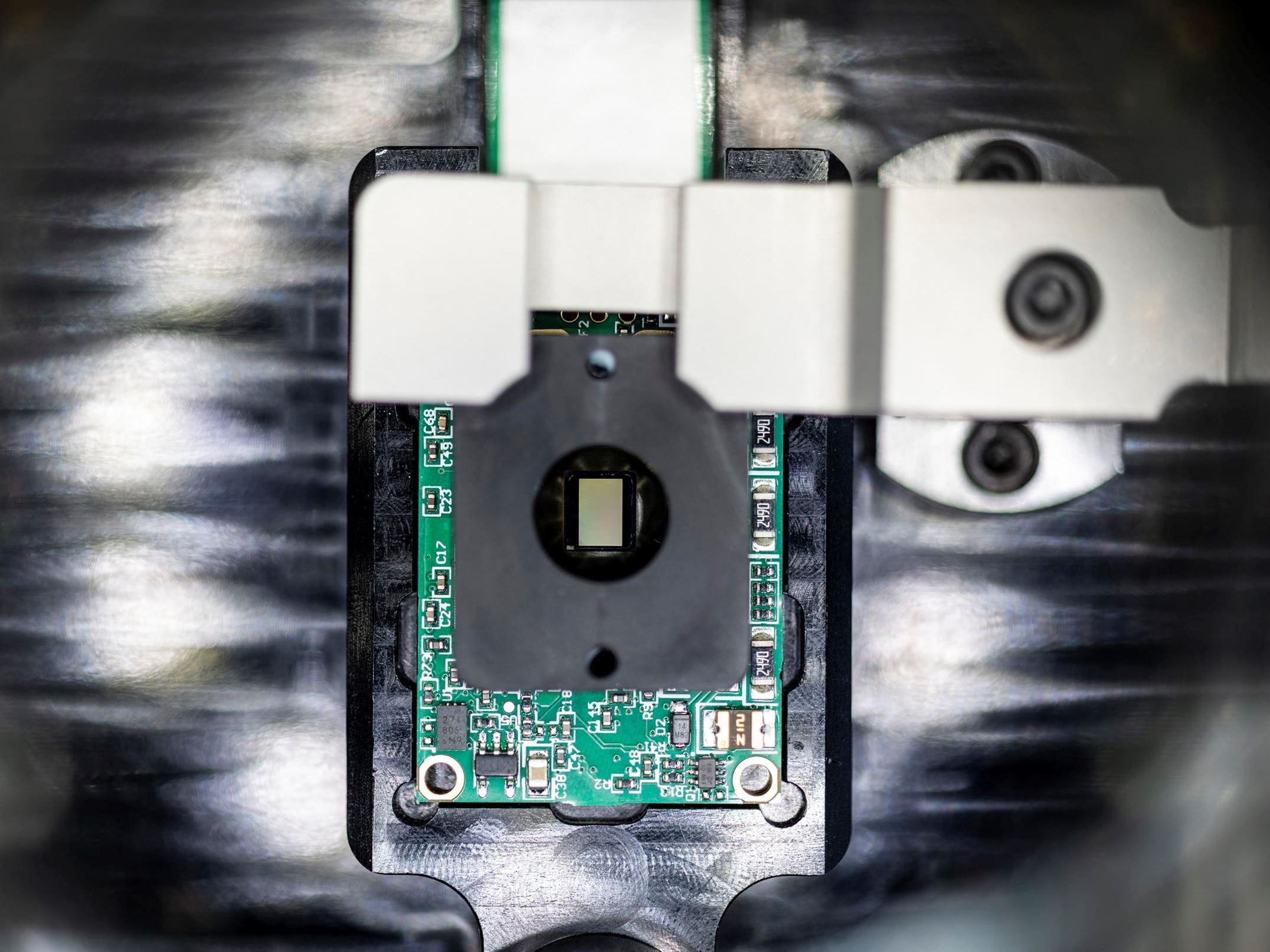

What is active alignment? Aligning an image sensor to a lens while actively reading image data from the sensor.

High performance

Flexibility

Proven technology

Products

ProCam® Prototyping

Consulting and engineering services for camera and LiDAR alignment

Our service to develop the best possible camera module according to your requirements. The service includes ongoing in-house manufacturing of prototypes and small series.

- Design optimization for the best possible active alignment process

- The alignment is done in the sub-micrometer range in all 6 axes (tilt, shift, focus, rotation) to achieve the optimum image quality

- Support for choosing the best manufacturing strategy based on your demands e.g. batch size and cycle time

More information

Our services at a glance:

- Joint optimization of your camera sample for the active alignment process

- Initial inspection of the lens with the ImageMaster® HR

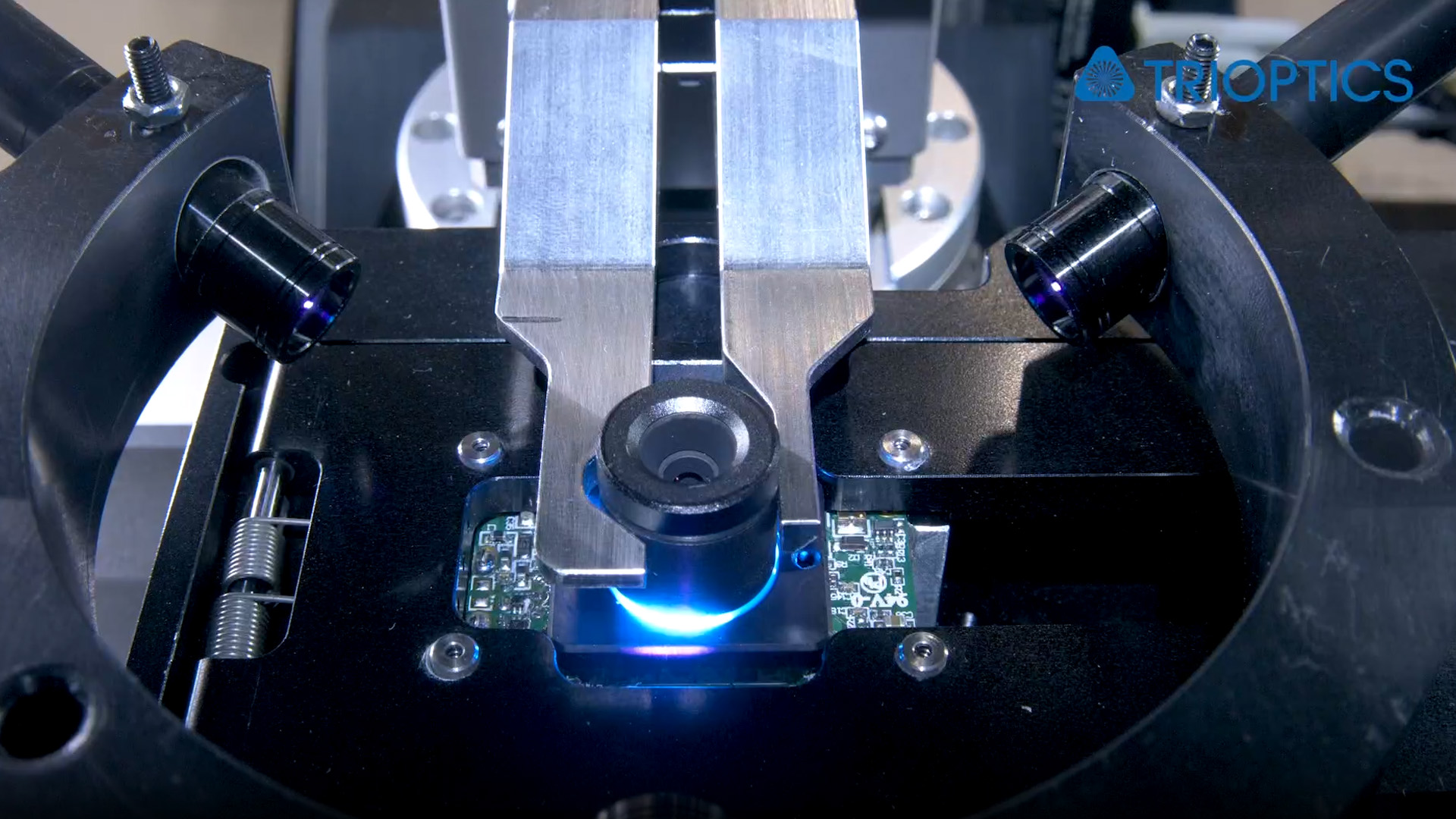

- Active Alignment including UV curing with ProCam®

- Oven curing

- Final quality control and detailed analysis by CamTest

- Finding the best configuration for your series production by using ProCam® and CamTest

We are happy to assist you with the choice of the adhesive. You will also receive the evaluations and measurement results for traceability and analysis.

ProCam® Lab

Entry-level active alignment system for R&D and Prototyping

With the new ProCam® Lab, we offer the ideal solution for customers who want to master the critical challenge of active alignment and assembly of high-precision camera modules with a small number of pieces. Customers can easily get started in the camera business and optimize their prototypes for later series production.

In addition to the purchase of our active alignment system ProCam® Lab Basic, we also offer a full package to set up a complete assembly line. The full package includes, among others:

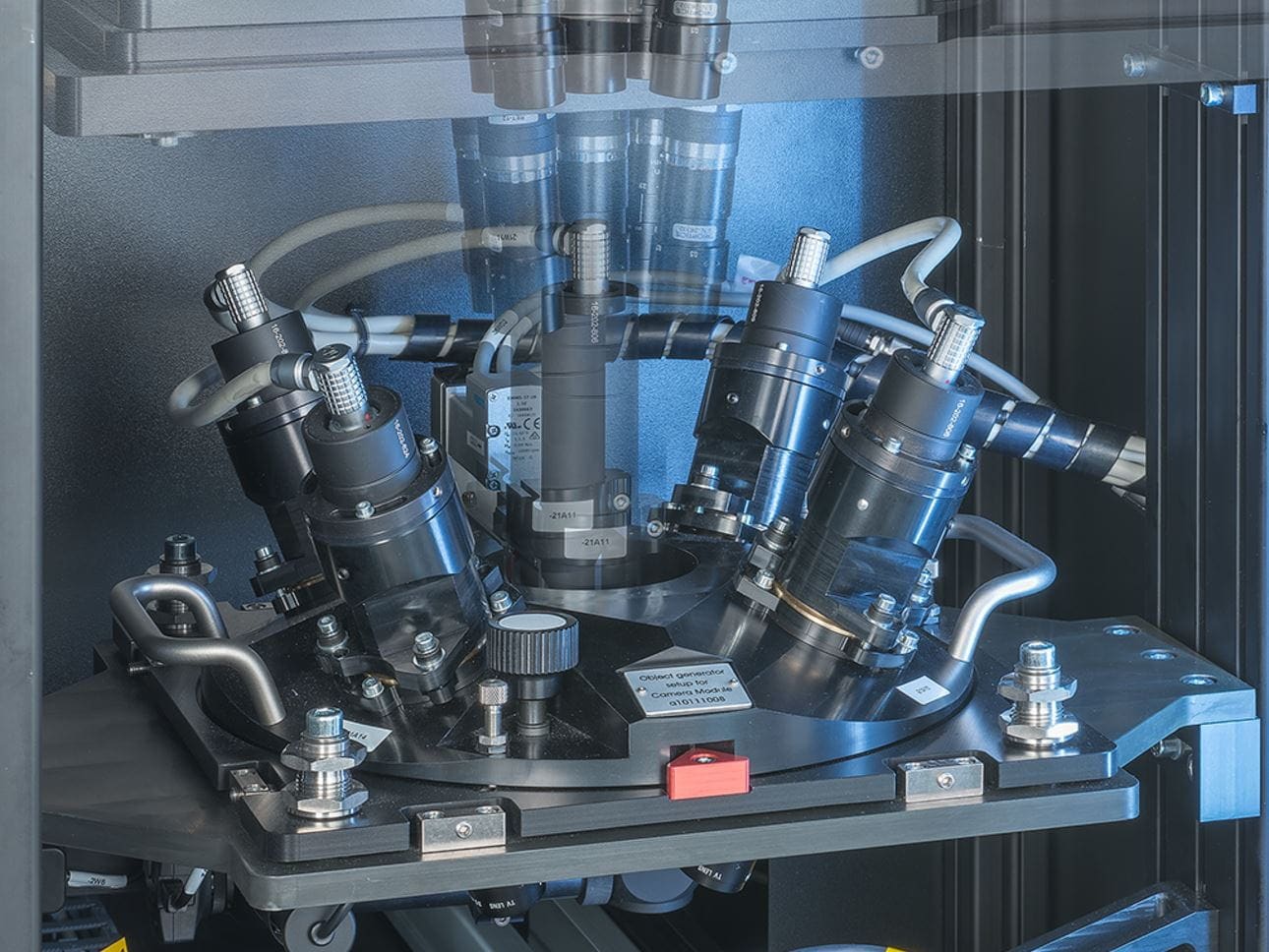

- Object generator, Dispense module, UV curing module

- Thermal curing oven and freezer for glue storage

- Sample specific workpiece carrier and lens gripper

ProCam® Align Smart

Versatile active alignment system for low production volumes

The ProCam® Align Smart is a premium solution for optimizing the optical performance of camera modules through active alignment.

- Automatic glue dispensing

- Alignment of the optics to the sensor or vice versa

- Precise adjustments for translation, tilt, focus and rotation to allow for optimal image quality

- Process ends with automatic UV-curing

More information

- Active alignment within sub-micron/sub-arcmin precision

- Up to 6 degrees of freedom

- Real-time MTF characterization and final MTF test

- Active alignment of wide-angle optics up to FOV 140° (FOV up to 170° possible after individual clarification

- Innovative target projection for infinite-finite and finite-finite conjugated samples

- Dual-/Stereo- and Triple-Camera alignment as well as LiDAR alignment on request

- Easy change-over procedure using kinematic mount

- Basic machine including control system, hardware and software, operating elements and displays

- Customized instrument options: dispenser (application-specific), object generator (camera-specific), workpiece carrier, UV, gripper, camera connection incl. frame grabber (camera-specific)

ProCam® Compact

Entry-level production system for active alignment of medium volumes

ProCam® Compact is a cost-effective entry-level system for series production of a wide range of camera applications. The robust production device offers high-quality measurement technology and precision with low maintenance effort.

- Outstanding productivity and efficiency

- Small footprint – high output

- One-day-installation (for pre-configured devices)

- Fast product changeover, i.e. change of different camera types due to flexible design of the machine

More information

- Quick change of WPC, gripper and UV-holder

- Product type change within 10 minutes possible (if the sensor of the product does not change)

- Most precise measurement results on the market

- State of the art algorithms of the ProCam® software enable best measurement results in camera alignment

ProCam® TT

Full-production system for active alignment of high volumes

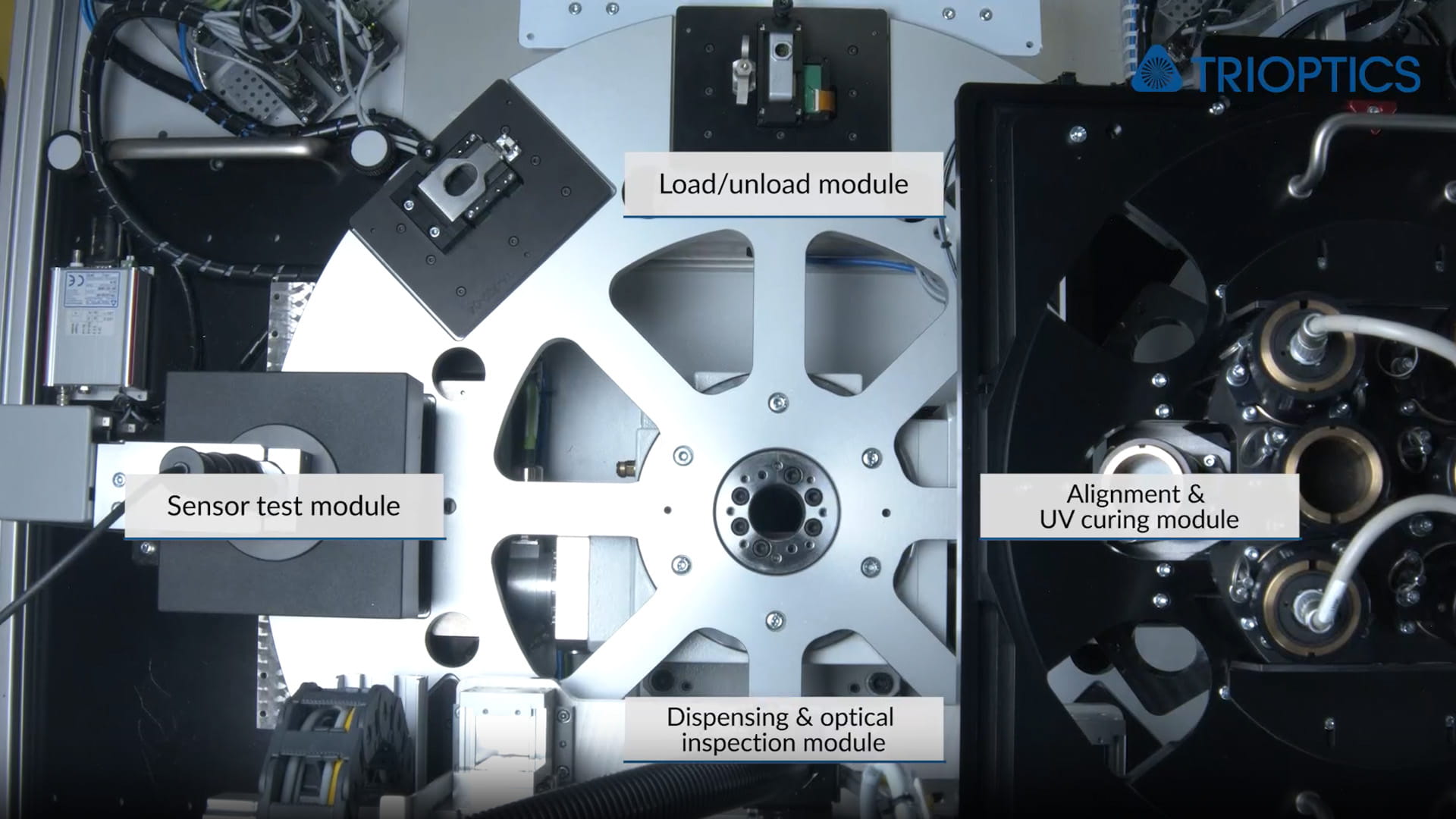

ProCam® TT is a highly automated, high performance system for active alignment and assembly of cameras and LiDAR systems with a very small footprint.

- Cycle time 12 seconds/ 300 units per hour (depending on the individual customer’s camera data)

- Fast product change within the cycle time

- Manually operated or integrated into an automated production line

- High precision collimator target generators

More information

- Active alignment within sub-micron/sub-arcmin precision

- Up to 6 degrees of freedom

- High-precision adhesive dosing unit and image processing controller

- Active alignment of wide-angle optics up to FOV 180° (possible after individual clarification)

- Double/stereo and triple camera alignment and LiDAR alignment on request

- Small footprint: 1400 mm × 1480 mm × 1875 mm

- Comprehensive data interface for traceability and analysis

- Connection to MES and host computer

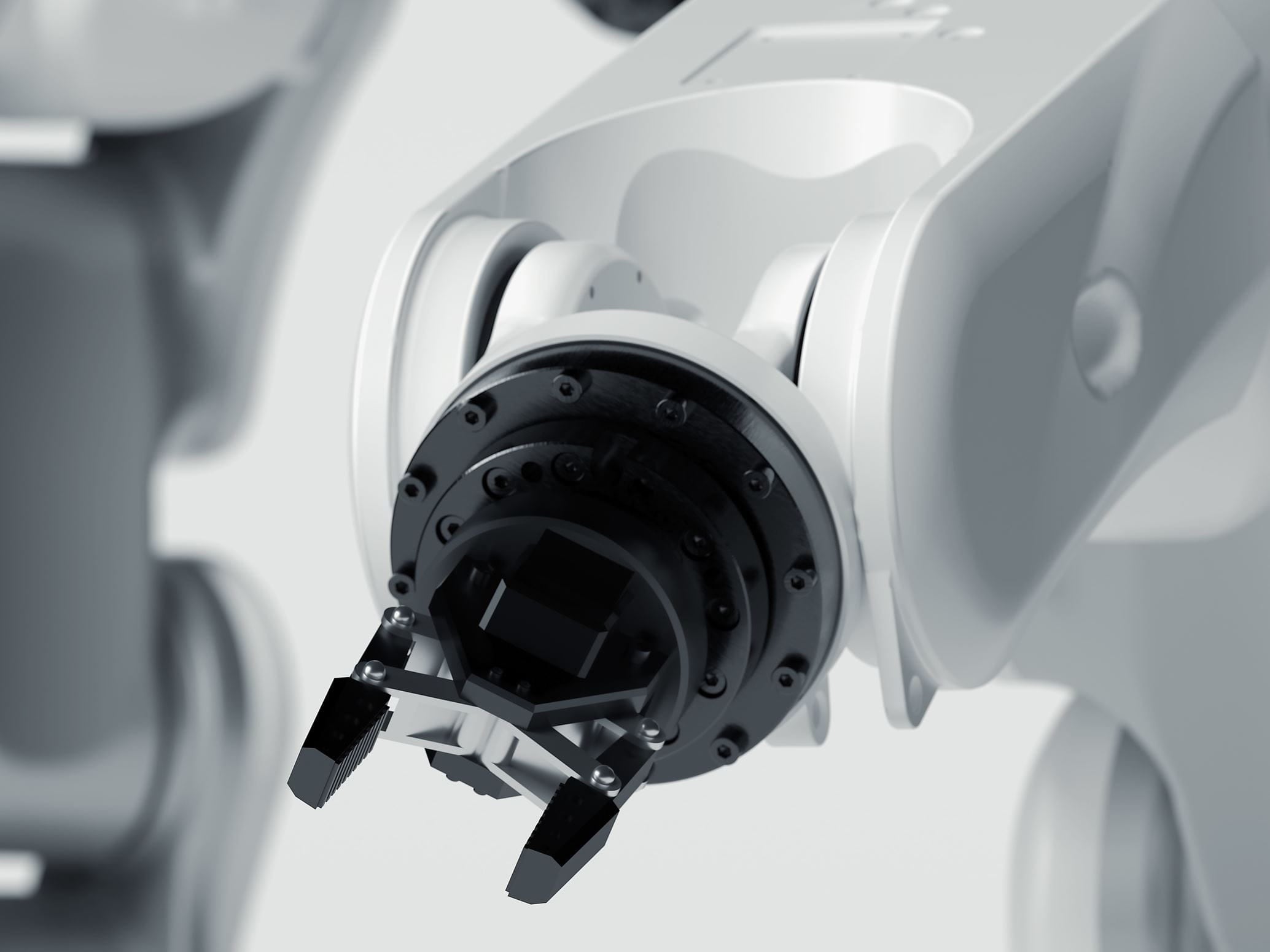

- Variable enclosure for manual loading or automatic robot loading

- Various test modules can be integrated on request

- Basic machine including control system, hardware and software, operating elements and displays

- Customer- and application-specific device options: Controller rack, load/ unload function, dispenser, object generator, workpiece carrier, UV unit, gripper, camera connection

Videos

Software

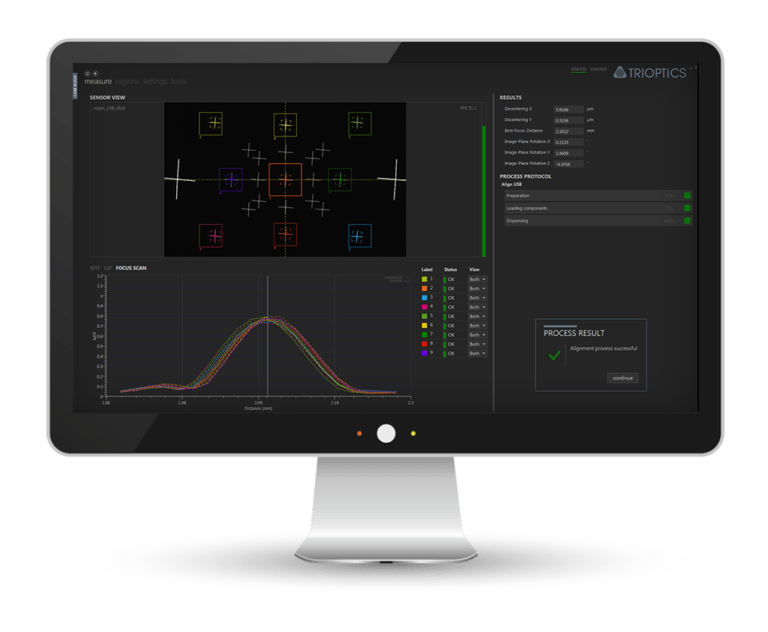

ProCam® Software

The ProCam® software consists of components for the fully-automated active alignment process:

- Using high precision image analysis algorithms, all relevant parameters for the accurate alignment process such as the MTF at multiple field positions and the tilt of the image plane are automatically analyzed in real-time and used in the alignment process.

- All stages of the alignment and measuring process are software-controlled by ProCam®

- With the integrated scripting tool, the measurement and alignment process can easily be tailored to specific customer needs and products.

- The measurement data can be saved in a database so that the process is completely traceable.

- The setting of individual configuration files enables a quick product change between different camera types.

Upgrades

Robot loading

Plug & produce collimator dome

Sensor test

Multi-position Dome

In the development and prototyping phase, many customers want to try out different camera configurations and measurement positions.

The new Multi-position Dome from TRIOPTICS has been developed exactly for this trial and error phase and maximizes flexibility in camera production and testing. The set-up of the collimators can be changed with a few simple steps and allows a continuous adjustment of the collimators. Minimum and maximum angles are quickly adjusted and positioned. Three different sensor formats 1:1, 4:3 and 16:9 can be tested in just one device thanks to the Multi-position Dome.

In concrete terms, this means time and cost savings when changing products. The numerous adjustable measurement positions make camera production and testing more flexible than ever before.

The new Multi-position Dome is now available as an upgrade for ProCam® Lab, ProCam® Align Smart and CamTest Focus.

ProCam® Product request

Are you interested in a product and would like to receive a quote?

Whether you need advice or already have specific requirements, we will be happy to help you!

Use our contact form and get quick feedback from our experts.Our Newsletter – Your advantage in knowledge

Be one of the first to experience our product novelties and innovative application possibilities.