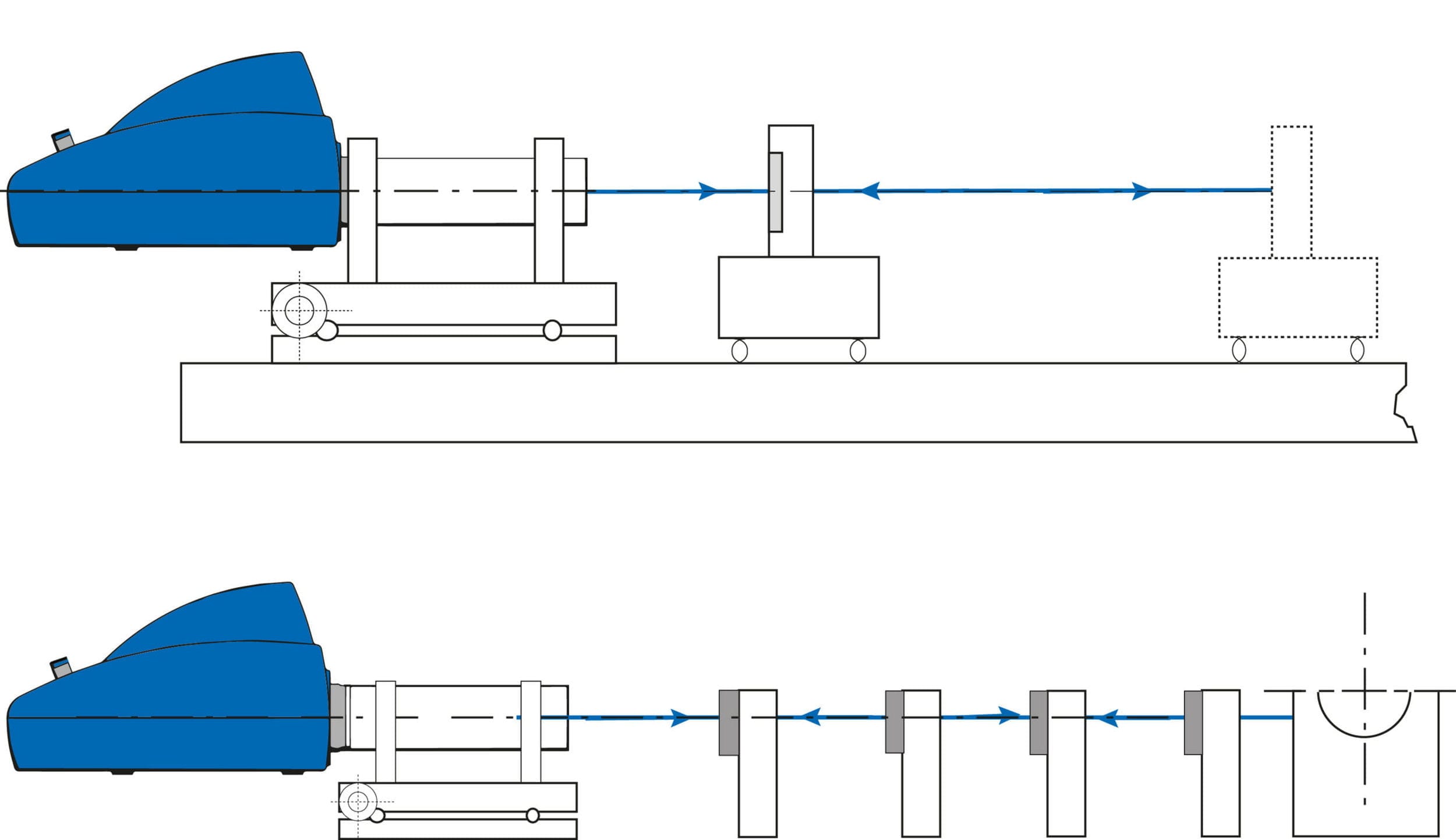

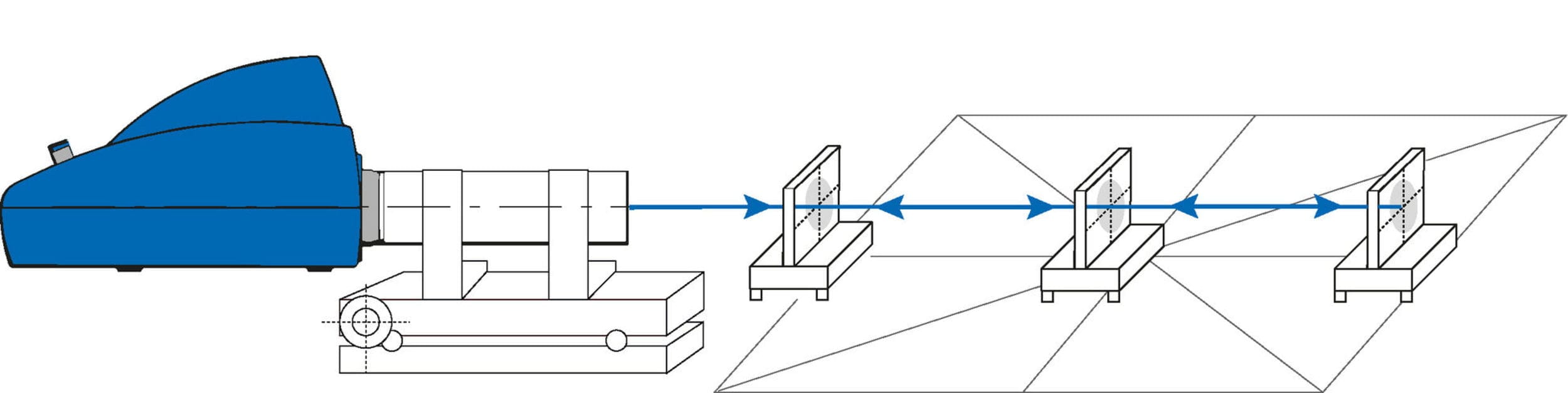

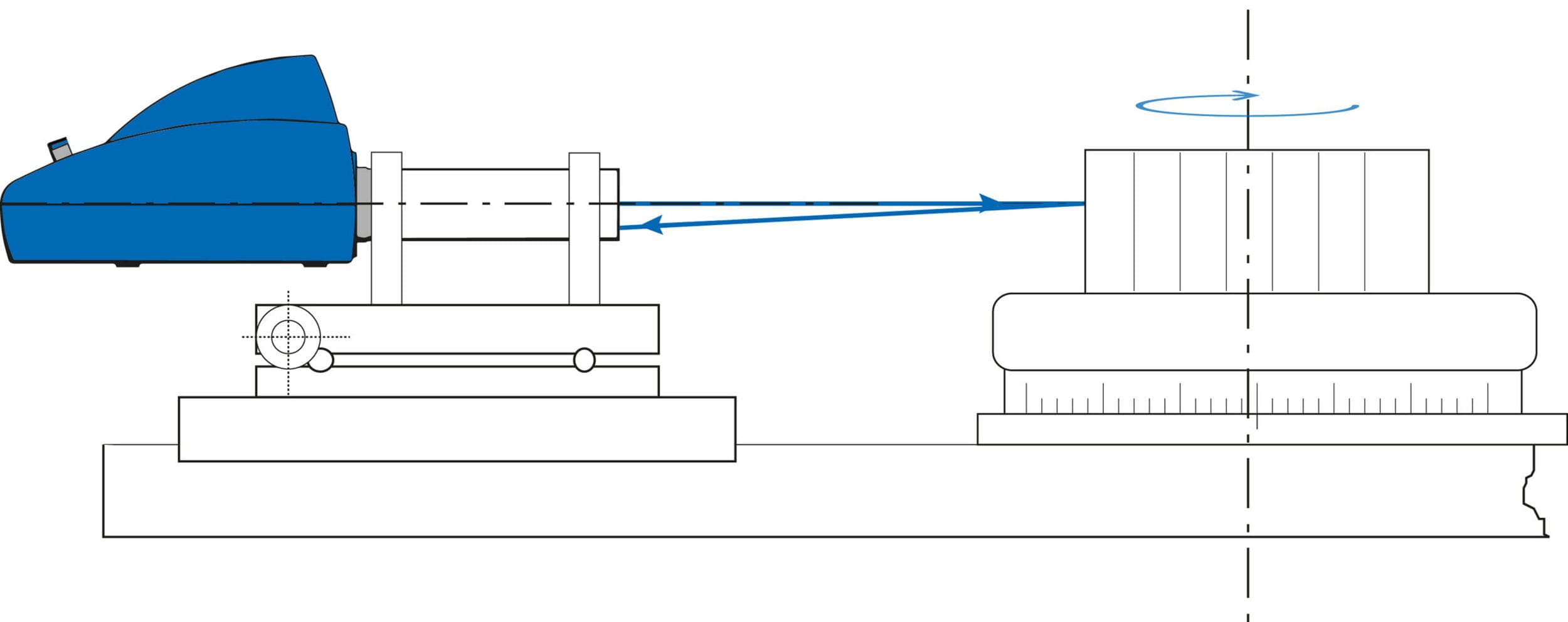

Optical measurement technology ensures precision in mechanical engineering

The precise measurement of machine components is a frequent requirement in mechanical engineering in the context of quality inspections. The focus is on a high level of precision as well as simple and software-supported operation. These requirements are met to a major extent by non-contact, optical measurement devices.