OptiSurf® LTM

High precision center thickness and sag value measurement of single lenses and doublets

In optics production, the high quality of the single lens is the prerequisite for high-precision optical systems. With the OptiSurf® LTM (Lens Thickness Measurement), TRIOPTICS offers a precise center thickness measurement system for single lenses and doublets that seamlessly integrates into any production process. The high precision low-coherence interferometry is based on the established OptiSurf® technology and measures single lenses and doubles with a glass thickness of up to 150 mm with a precision of ±0,5 µm. The non-contact measurement system is gentle on sensitive surfaces and coatings. In addition to the center thickness, the sag value can also be determined.

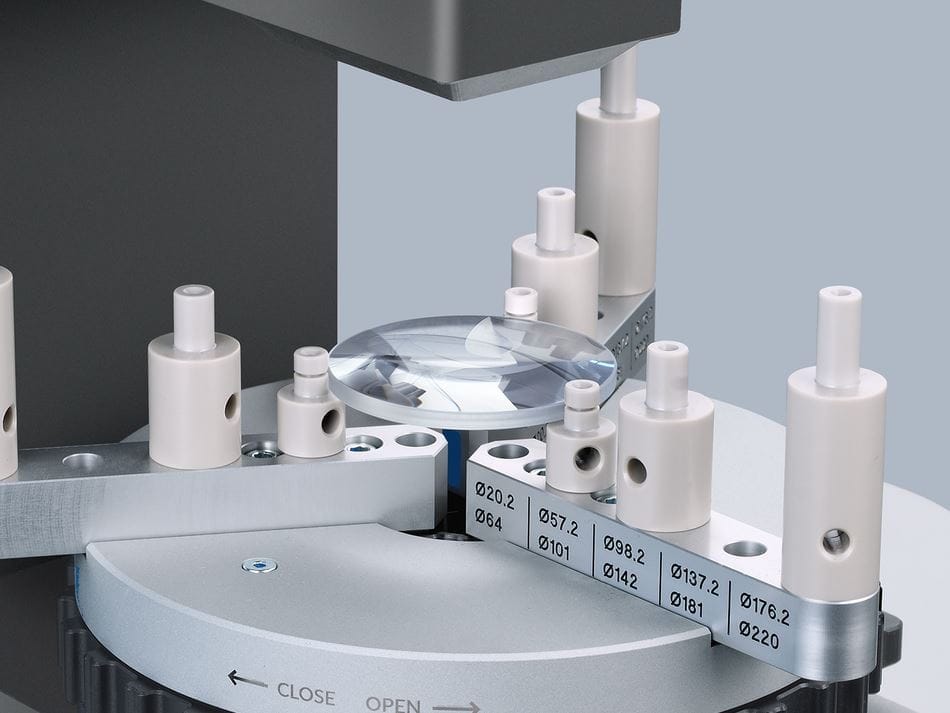

The optimization for use in production is particularly evident in its simple and stable handling. The OptiSurf® LTM is equipped with vibration damping and a self-centering mechanical clamping chuck. Two clamping chucks are available to choose from depending on the sample size (standard: 8 mm … 200 mm, micro: 1 mm … 30 mm). This eliminates any adjustment of the sample and the measuring process can be carried out safely, quickly and independently of the operator.

Simple operation is ensured by an integrated touch screen. For a straightforward data input a database can be called up via a network connection. The customer-specific connection of a barcode scanner is possible.

The optimization for use in production is particularly evident in its simple and stable handling. The OptiSurf® LTM is equipped with vibration damping and a self-centering mechanical clamping chuck. Two clamping chucks are available to choose from depending on the sample size (standard: 8 mm … 200 mm, micro: 1 mm … 30 mm). This eliminates any adjustment of the sample and the measuring process can be carried out safely, quickly and independently of the operator.

Simple operation is ensured by an integrated touch screen. For a straightforward data input a database can be called up via a network connection. The customer-specific connection of a barcode scanner is possible.

Highly precise

The used, established short coherence interferometry provides non-contact measurement results with an accuracy of up to ±0.5 µm. Vibration damping ensures reliable and environmentally independent measurement results.

Fast

Due to the mechanical chucks, measurements without adjustment of the sample are possible. The data input and output is fast and comfortable via the network connection or a simple design editor.

Reliable turnkey solution

With its integrated touch screen, the OptiSurf® LTM is particularly compact, robust and easy to use. Customer-specific adaptations such as barcode scanners, printers and other aids are of course possible.

Software

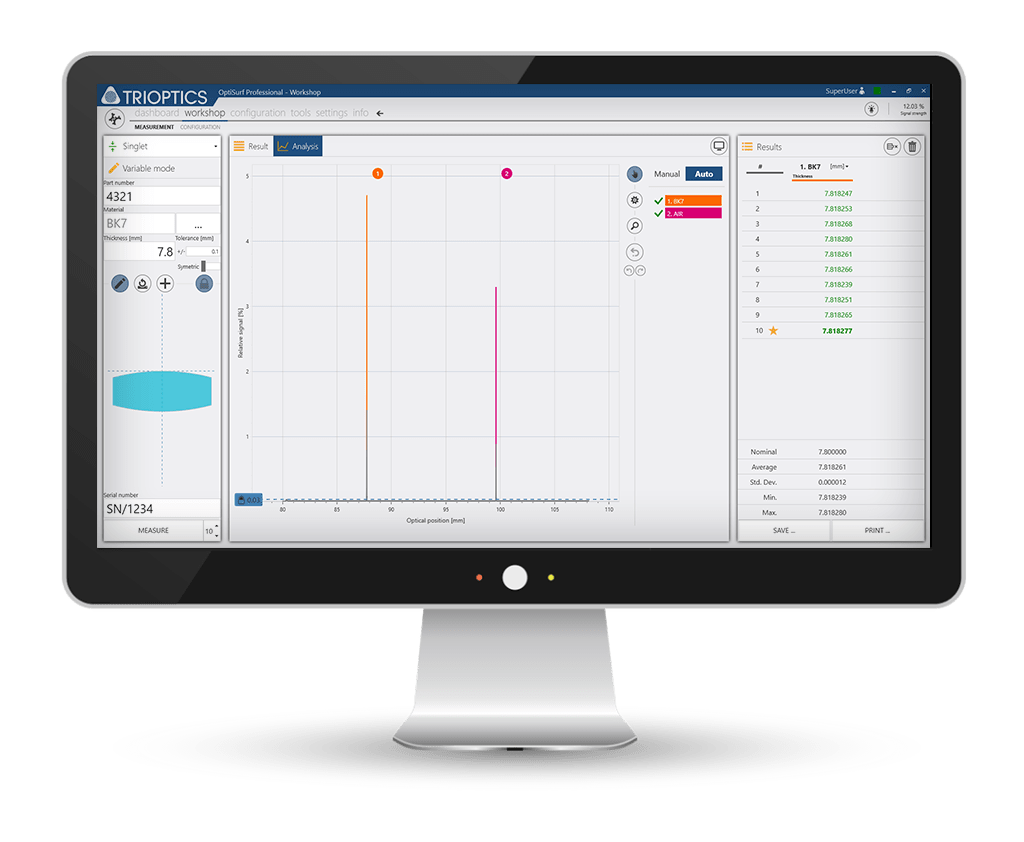

OptiSurf® LTM Software

Simple handling –fast results

Just like the remaining design of OptiSurf® LTM, the software is also optimized for the quick measurement of single lenses as needed for smooth daily usage in optical workshops. The measurement settings are easy to configure and the results are presented in a way that is simple to understand. In addition, a pass/fail analysis of the measurement result is performed.

- Thanks to the easy-to-follow structure of the user interface, the measurement process is goal-oriented and the results are shown in a way that is easy to understand

- Automatic surface identification for fast and precise measurements

- Direct quality analysis by means of pass/fail display as well as statistical analysis of measurement results

- Direct embedding of the system in your processes, ensuring fast and error-proof data processing: The lens design can be entered directly from Zemax or via the OptiCentric® interface or via the practical Design Editor

Upgrades

LensGage Modul

OptiSurf® LTM Product request

Are you interested in a product and would like to receive a quote?

Whether you need advice or already have specific requirements, we will be happy to help you!

Use our contact form and get quick feedback from our experts.Our Newsletter – Your advantage in knowledge

Be one of the first to experience our product novelties and innovative application possibilities.