Alignment turning

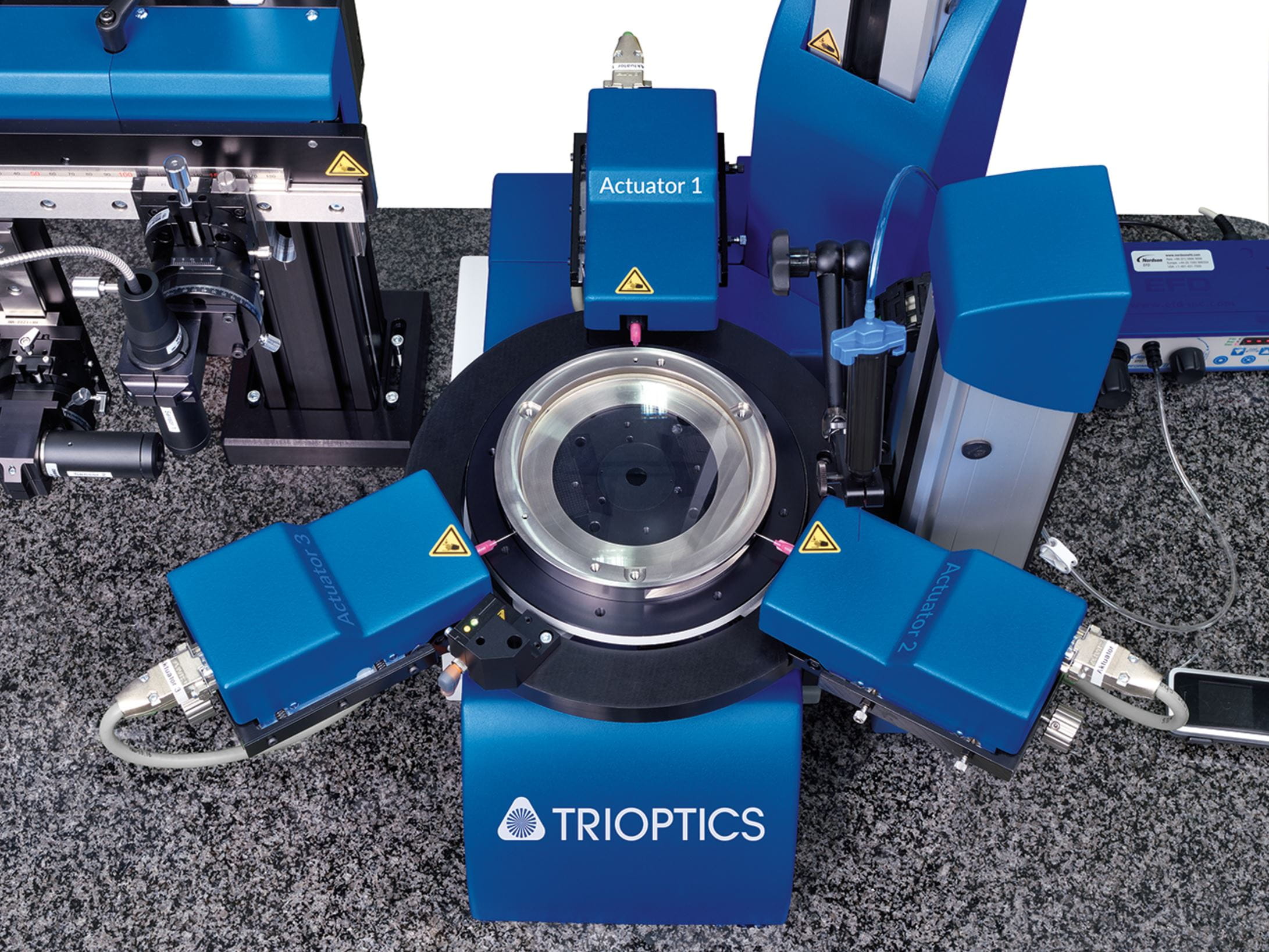

Want to efficiently produce high-precision optical systems? Then it's worth taking a closer look at alignment turning. This unique process manufactures the cell edge and flange surfaces of mounted lenses and lasers so that the symmetry axis of the cell is aligned with the optical axis of the lens or laser beam. The proven OptiCentric® centration measurement system is used for optical measurement. We combine this with an ultra-precise turning machine.

Applications

Mounted lenses

With their universal design and versatile metrology options, the alignment turning stations ATS can process all mounted lenses and lens assemblies, including those with infrared and aspherical lenses or with mounted cells that cannot be glued. The choice always falls on the ATS when it comes to increasing efficiency. Here the system has not only excelled in mass production but also in the manufacture of customized lenses.

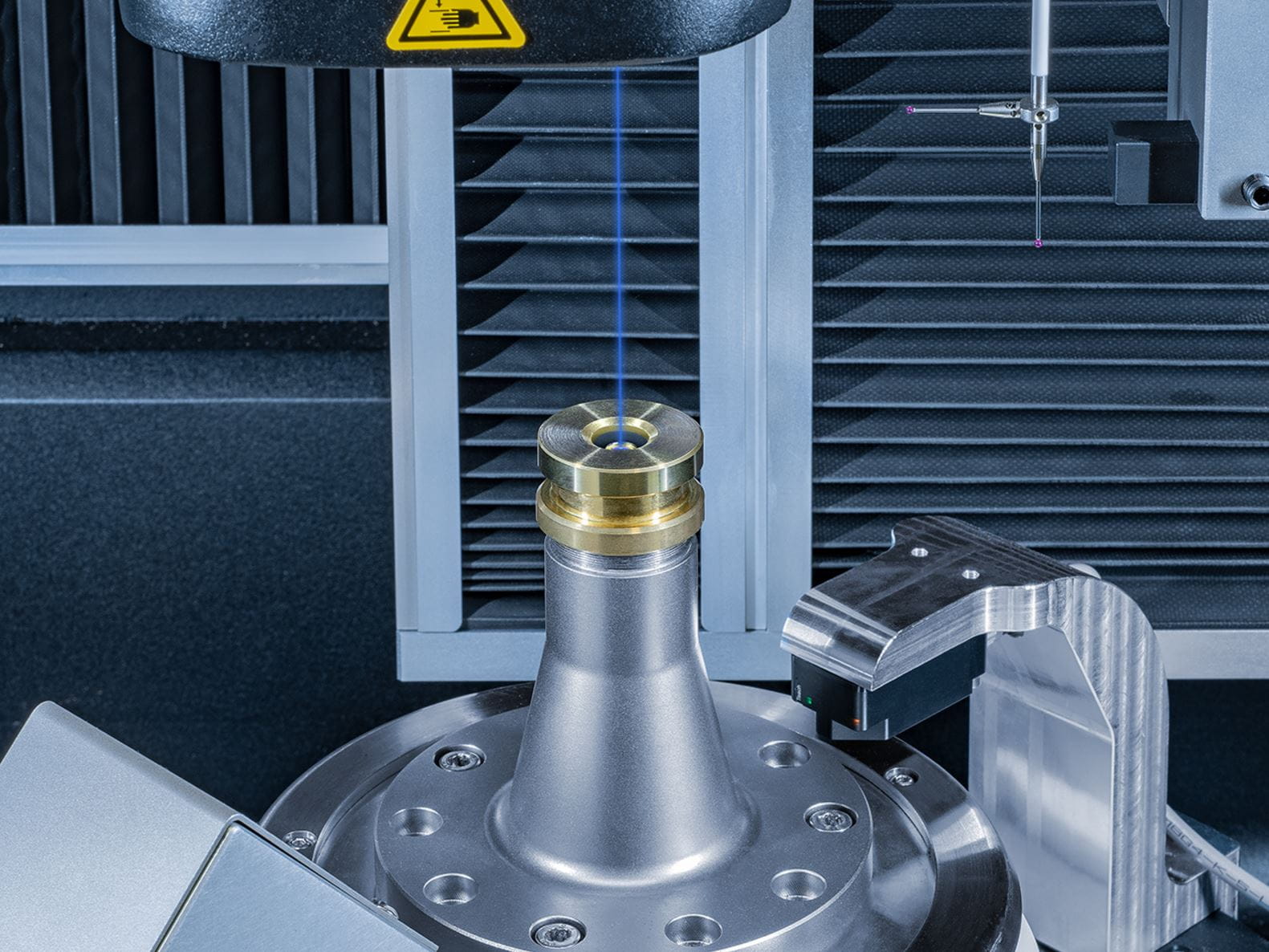

Laser diodes

Just like the alignment of passive elements such as mounted lenses, the ATS also allows the alignment of laser diodes. Here, too, alignment turning eliminates the need for active alignment of the laser during assembly. For these active samples, the generated laser beam serves as the centration axis. While the correction of the inclination is already possible in the sytem’s standard configuration, a second optical measuring arm must be installed for the additional correction of the displacement. The processing is carried out in the same way as for the passive elements.Coffee Break

No time for long explanation videos?

Get the essentials on a wide range of technology topics during a coffee break.

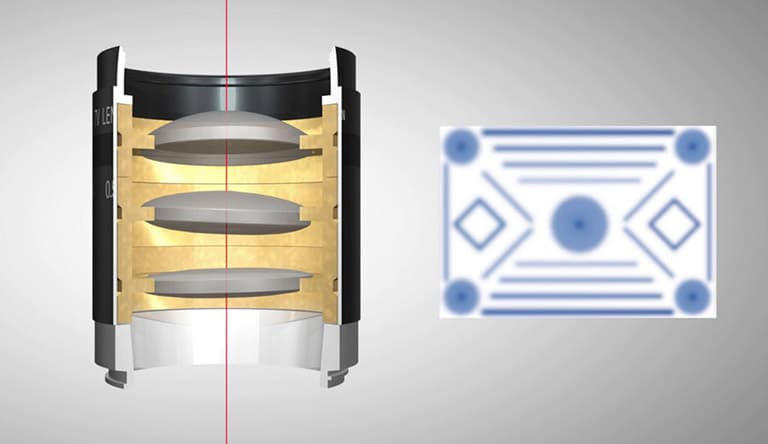

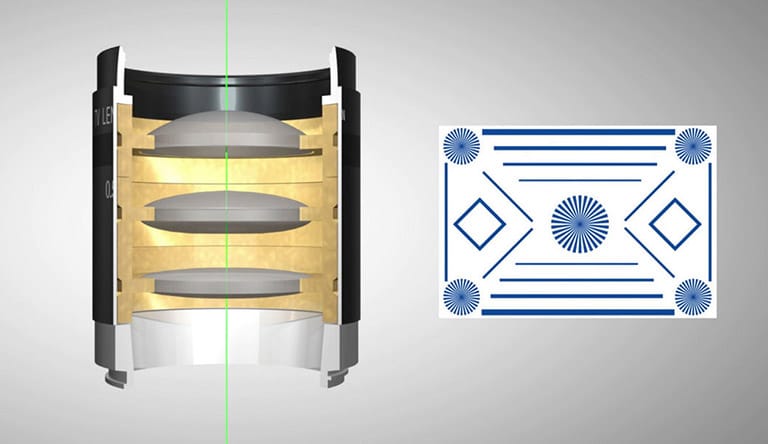

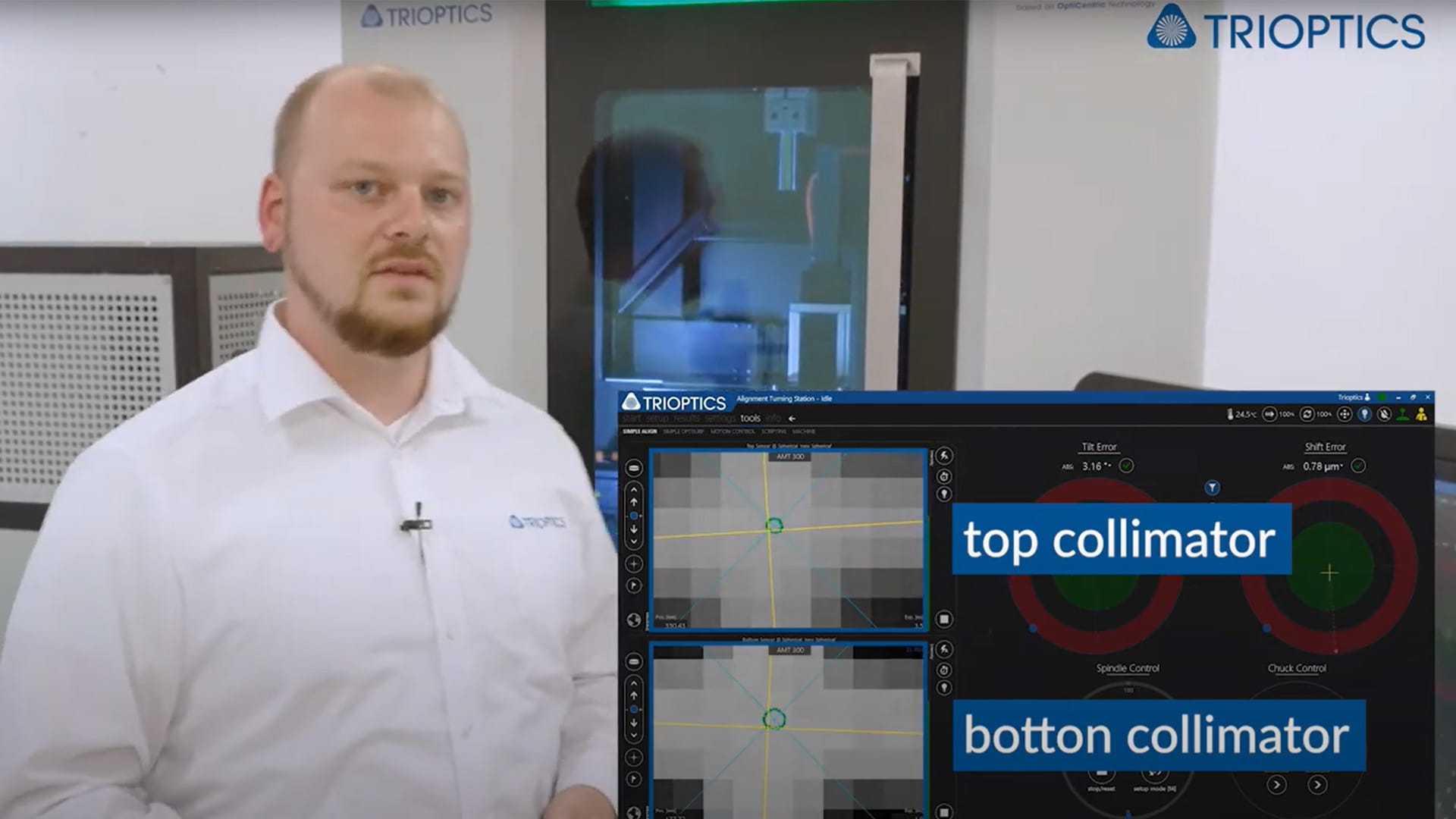

Machining mounted lenses consisting of multiple elements with alignment turning

It is well known that mounted lenses consisting of several optical elements can also be machined by means of alignment turning. However, you can see in this video how important the inner optical surfaces are and how they are taken into account during machining in the ATS alignment turning machine.

Success Story

Strong trust in our expertise

ATS increases the precision of lenses to a maximum at Sill

Sill Optics successfully implemented the TRIOPTICS Alignment Turning Station into their production process. Martin Kolb, Project Manager Laser Optics, explains the benefit: “When attempting to accurately align the mechanical and optical axes, conventional methods can result in deviations of a few angular minutes. These tilt errors would cause unacceptable inaccuracies in our high-precision multiple lens systems. Thanks to TRIOPTICS’ ATS, we can reduce the tolerances of residual tilt errors to a few arc seconds. Adjustment turning increases the precision of our lenses to a maximum. We therefore use the ATS regularly for our high-precision lenses.”A quality leap in precision manufacturing at WILD

WILD recently added a new alignment turning station – ATS 200 UP – to its machine park. The machine is a pivotal element for utmost precision and efficiency in the manufacturing of complex optics.

„”In future, alignment turning in the quality we can now offer will open the door to new designs with very small air gaps.““

Stefan Werkl, Head of the Optical Technology Division at WILD

Are you enthusiastic about the possibilities offered by alignment turning, but need a solution that is cleanroom-compatible? Then take a look at our OptiCentric® bonding systems!

Knowledge base

- Measurement and alignment turning of optical assemblies

- Alignment turning with alignment chuck

- CNC alignment turning

Measurement and alignment turning of optical assemblies

Alignment turning is the only method by which relevant parameters of a mounted lens can be aligned, in particular the gap between two apex points and the contact surface. In addition, a large number of different cell sizes can be processed. And finally, high precision turning machines achieve excellent production accuracies of up to 0.5 µm.

Variable preconditions and options

The lens is already fixed in the cell during the alignment turning process. This means that low-stress adhesives with very long curing times can be used for highly precise optics. Similarly, the lenses can be crimped or held by screw rings when the available adhesives are not suitable for the intended application. In order to achieve high accuracy TRIOPTICS has integrated additional measurement technology into its alignment turning stations, alongside the high-resolution autocollimators. These include tactile and optical test systems that ensure a highly accurate measurement of the relevant mechanical parameters. This means the highest precision is achieved by a gradual machining process, in which the cell accuracy is checked after each machining step. The cells used in alignment turning do not need to meet exceptionally tight tolerances before machining. The cell offset only needs to be large enough to meet the required tolerance after machining.

The distance from the lens vertex to the upper contact surface can be manufactured with an accuracy of up to ±0.5 µm. Similarly, the diameter can be manufactured with an absolute accuracy of ±2 µm. The remaining centration error can be reduced to less than 0.5 µm by using a suitable alignment chuck. Moreover, a low coherent interferometer can be used to measure the center thickness on the machine, so that the contact surfaces can be manufactured with high precision with respect to each lens vertex. Multiple mounted lenses manufactured by alignment turning are then assembled to an objective lens. The method of machining in the micron range ensures that all lenses are aligned to each other. This allows mounted lenses to be assembled in a tube without further adjustment steps.

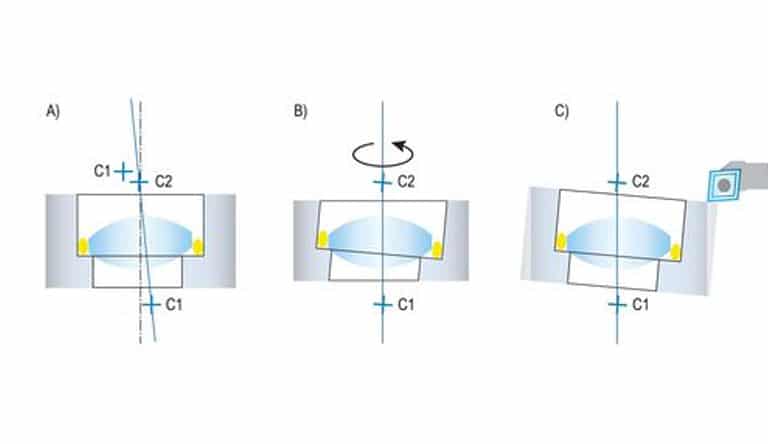

Alignment turning with alignment chuck

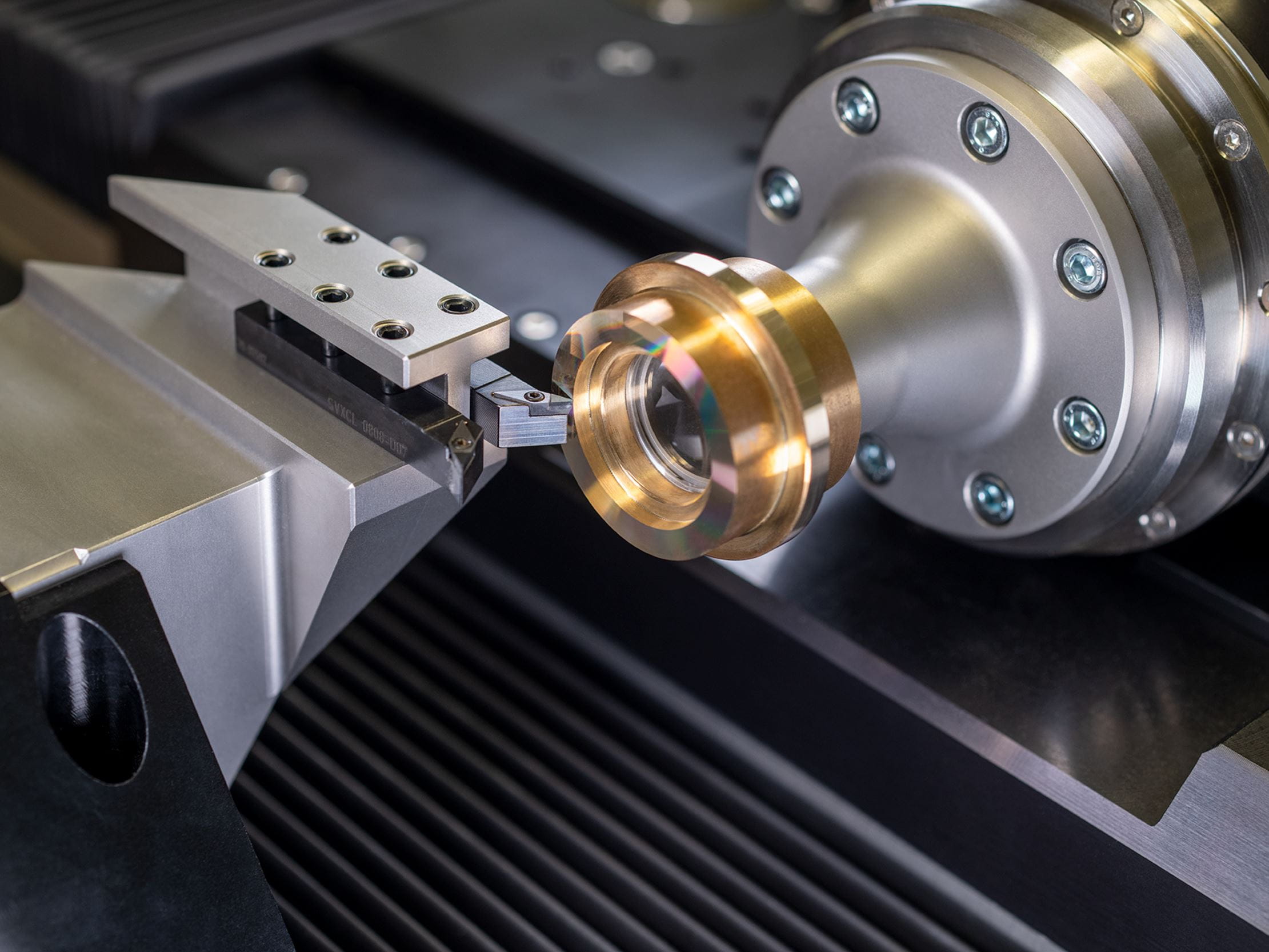

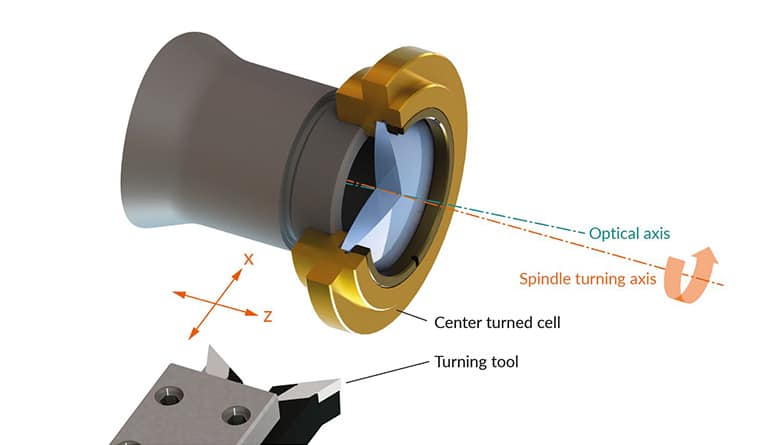

The alignment turning method using an alignment chuck is described in the figures below (Fig. 3). Here, first the lens cell is fixed in an adjustable alignment chuck with the lens in place. Then the position of the optical axis of the lens to the spindle axis is measured with the OptiCentric® system. Using this alignment chuck, the lens is then aligned so that its two centers of curvature are located as closely as possible to the axis of rotation of the spindle.

Then the spindle is rotated and the contact surfaces of the cell are machined with a sharp (diamond) turning tool, resulting in a precisely machined surface of the cell, aligned parallel to the spindle axis. In addition to the outer surface of the cell, it is also possible to machine the front and rear contact surface during the turning process. To do this the turning tool is moved perpendicular to the spindle axis instead of along the optical axis.

CNC alignment turning

Alignment turning on the ATS-C is implemented without an alignment chuck. The mounted lens is held on the horizontally mounted spindle and the optical axis is measured with OptiCentric® measuring technology. To adjust the mounting surfaces to the optical axis, the turning tool moves in x- and z-direction.Our Newsletter – Your advantage in knowledge

Be one of the first to experience our product novelties and innovative application possibilities.