Spherometer

Fast and efficient radius measurement of lenses

High Precision

Traceability

Versatility

Products

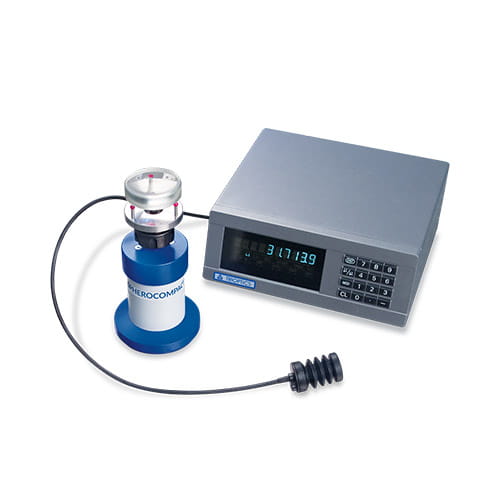

SpheroCompact®

Radius measurement in production

The SpheroCompact® allows radius measurements in production with accuracies of up to ±0.05 %.

- Multi-purpose use, particularly for highly curved convex and concave surfaces because small radii of up to +2.5 mm and -4 mm especially can be measured

- Its compact design allows SpheroCompact® to be used flexibly

- Spherometer optimized with regard to price and performance for use in manufacturing

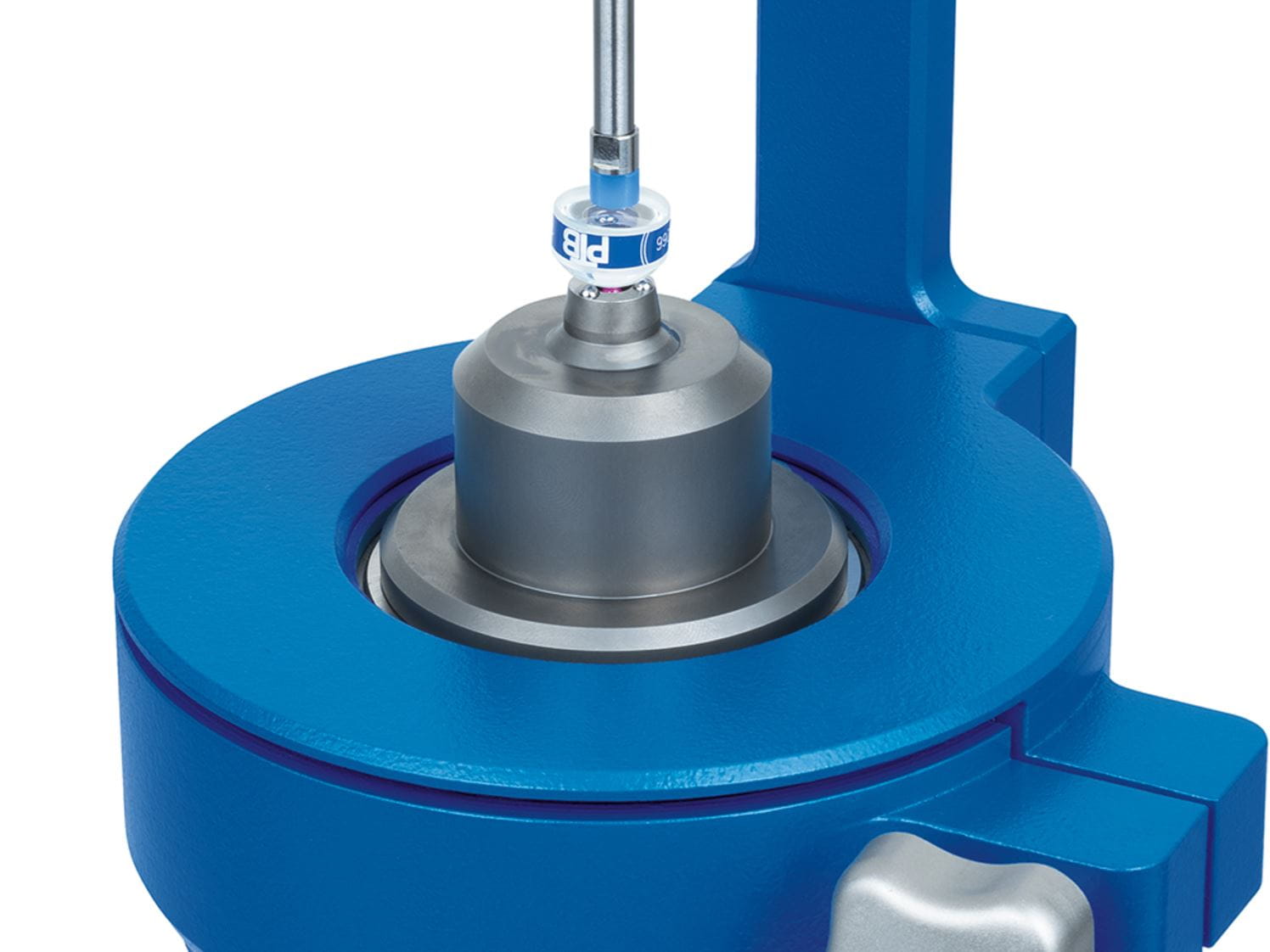

SuperSpherotronic® HR

Precise and reproduceable

The SuperSpherotronic® HR offers excellent accuracies of up to ±0.01 %.

- Radius measurement of convex and concave surfaces up to +3 mm and -6 mm

- Excellent precision for the measurement of highly curved surfaces with a large lens diameter by means of an increased travel of 60 mm

- Extreme resistance to mechanical deformation thanks to the use of tungsten carbide balls in the ring

UltraSpherotronic®

Highest precision

With an accuracy of up to ±0.005 % the UltraSpherotronic® reaches the highest measurement precision worldwide.

- Radius measurement of convex and concave surfaces up to +3 mm and -6 mm

- Excellent precision for the measurement of highly curved surfaces with a large lens diameter by means of an increased travel of 60 mm

- Extreme resistance to mechanical deformation thanks to the use of tungsten carbide balls in the ring

Software

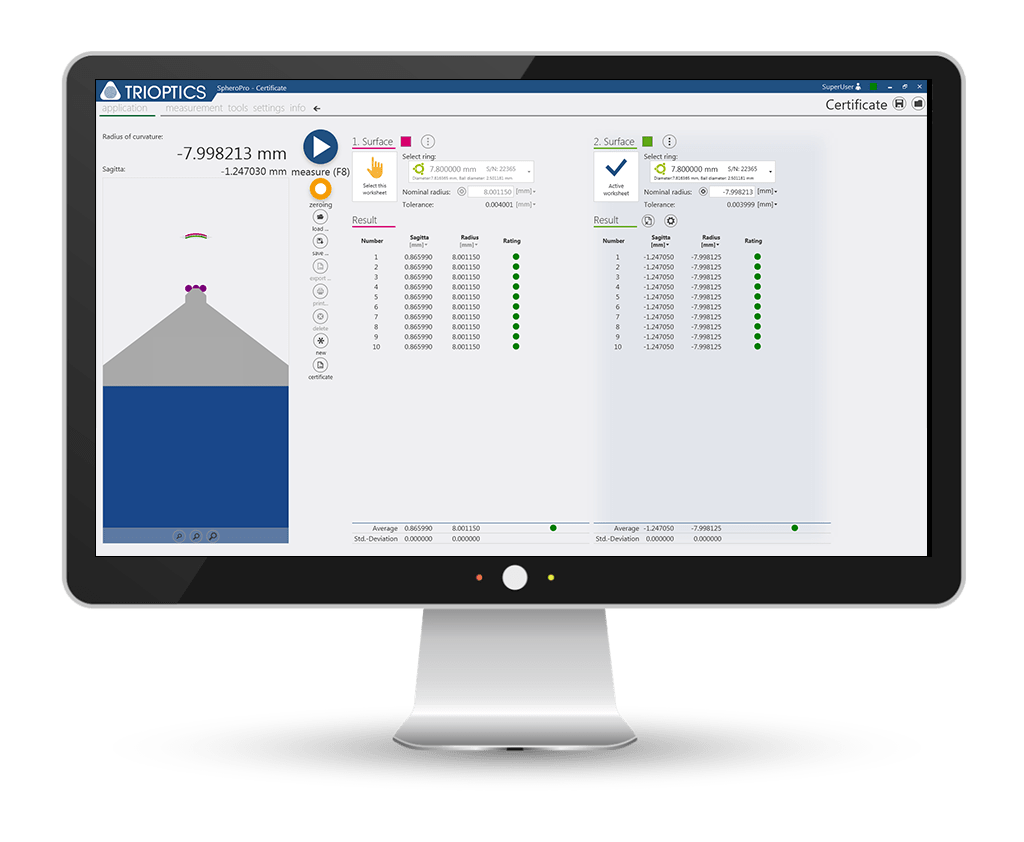

SpheroPRO

The user-oriented software SpheroPRO was designed to fully meet the requirements in real-life applications. The intuitive user menu permits the easy, quick and error-free determination of the radius of curvature of lenses via pre-configured measurement programs. The current test step can be controlled directly by a schematic representation of the measured radius of curvature (concave or convex). Quality control is performed by means of a continuous statistical analysis of values.

- Very easy handling through pre-configured measurement programs for various applications, e.g.: test tube and single surface measurements

- Fast check of test step and measurement process for plausibility through schematic representaiton of radius of curvature (convex/concave) and current number of measurements

- Continuous quality control through statistical analysis of measurements, including mean value, standard deviations and pass/fail analysis

- Intuitive storage and recall of measurement series for quality control

- Compact but comprehensive documentation in measurement certificates that can be stored digitally and printed

- Intuitive storage of templates (selected ring, nominal radius, selected tolerance)

- Ring calibration data are easy to import and, if necessary, update for product extensions or product checks

- To reduce general maintenance and space requirements, the software has also been designed for touch screen operation. This eliminates the need for a keyboard and mouse

Upgrades

Precision rings with ruby balls

(SpheroCompact®)

- Standard set (diameter): 12.5 mm, 25 mm, 50 mm, 75 mm, 100 mm, 125 mm

- Special sizes (diameter): 6 mm, 20 mm, 30 mm 38 mm, 40 mm, 150 mm, 225 mm

- According to customer requirements

Precision rings with tungsten carbide balls

(SuperSpherotronic® HR/UltraSpherotronic®)

- Standard set (diameter): 7.8 mm, 14 mm, 20 mm, 28 mm, 38 mm, 60 mm, 90 mm, 120 mm

- Special sizes (diameter): 12 mm, 14+3.5 mm, 20+1.8 mm, 28+1.2 mm, 48 mm, 75 mm, 150 mm, 225 mm

- According to customer requirements

Mechanical pressure pad

- Constant and fixed contact pressure between the sample and ring

- For small lenses with a low net weight

Foot switch

- Activation of the measurement process

- For efficient handling in series measurement

Spherometer Product request

Are you interested in a product and would like to receive a quote?

Whether you need advice or already have specific requirements, we will be happy to help you!

Use our contact form and get quick feedback from our experts.Our Newsletter – Your advantage in knowledge

Be one of the first to experience our product novelties and innovative application possibilities.